Mistakes I have made

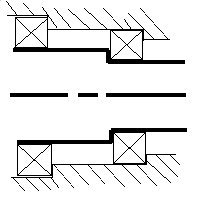

Some time back I designed a machine with a stepped shaft. The shaft was stepped to make assembly easier. In order to mount the shaft two different size bearings were specified. The two bearings were by the same manufacturer and in the same series. Both bearings were shown in the local bearing distributor catalog as being stocked. A schematic of the arrangement is shown above.

The drawings were sent off to the machine shop for manufacture and assembly. It was at that point that trouble arose. The machine shop called the bearing distributor and found that the smaller bearing had a thirty week lead time. I had made the assumption that since the bearings were shown in the catalog they were readily and quickly available.

We recovered by using two of the larger bearings. A sleeve was mad to fit over the stepped shaft so a larger bearing could be used where the shaft necked down. The diameter for the smaller bearing was then bored out to accept a large bearing.

The moral is never assume that you can easily get what is shown in the catalog. Always investigate the lead time for your parts.

Remember: If you don't do anything you never make mistakes.

0 Comments:

Post a Comment

<< Home