Neglect of variation, analysis of variance, Part 2

The experiment was to test the susceptibility of optical fibers to gamma radiation. I measured the attenuation (loss of optical transmittance) of the optical fibers as a function of radiation dose.

I ordered a spool of sample fiber from each manufacturer. I unspooled 20 meters of fiber. Snip, one specimen. I unspooled another 20 meters of fiber. Snip, a second specimen. I was now covered. Two specimens of each fiber. The data from the experiment at a given radiation dose looked like the sketch below.

But had I really allowed for variation? In retrospect, no. The two specimens were from the same spool. They were not independent samples. They would have identical raw materials and identical processing. From memory I recall that one of the parameters affecting radiation life of optical fibers is the hydroxyl concentration. But the two fibers from a specific manufacturer being of the same lot would have no variation in hydroxyl concentration.

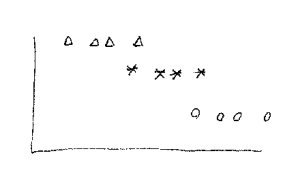

They should have been from different production lots separated in time. This would allow for variation in the lots of raw materials and variation in process parameters. Because my samples were not independent I could not really say conclusively whether the data from multiple lots would look like this:

Or perhaps this:

In the second case there is no statistically difference between the fibers.

It is not enough to have multiple specimens. You must also understand the reason for having multiple specimens. The point of multiple specimens is to try to capture and understand the true variability in what you are studying.

tags:

0 Comments:

Post a Comment

<< Home